2023/07/17

The volume of global textile production has set a new record again in 2021 after a slight decline due to COVID-19. The textile industry is increasingly mass-producing, mass-consuming, and mass-disposing as the world’s population increases. The production volume of polyester fiber is the largest, accounting for 54% of the total fiber production volume, and increased to 61 million tons in 2021. In addition, due to its excellent performance, polyester is not only used for textiles, but also has a wide range of other uses, such as PET bottles, food trays, and industrial films, making it an indispensable material in our daily lives.

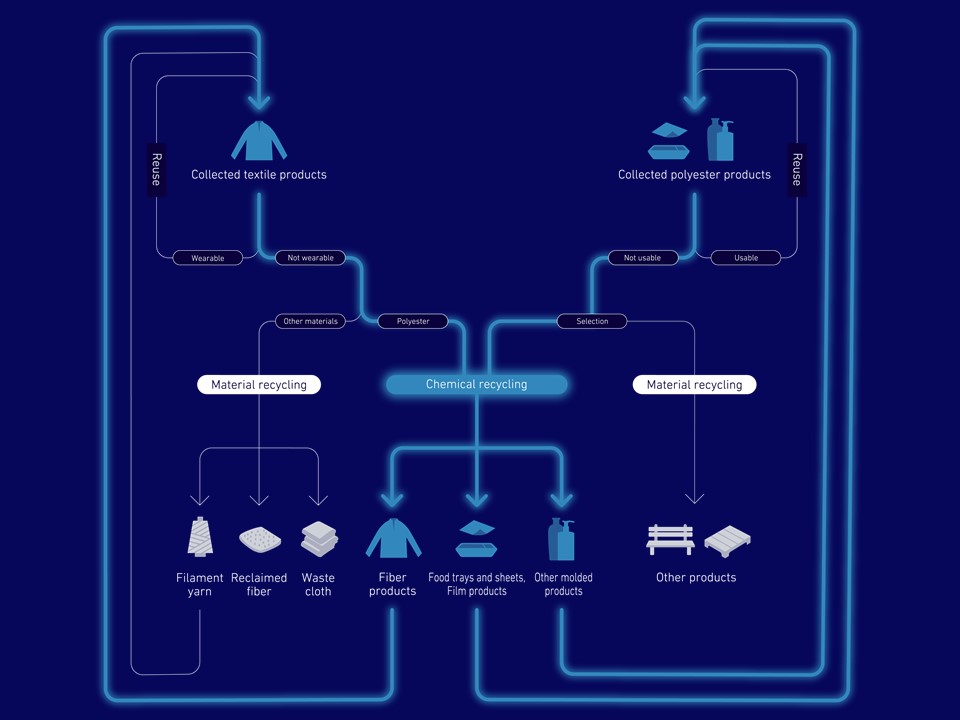

On the other hand, polyester is a material that can be easily obtained, so the problem of mass disposal has become apparent. Therefore, the utilization of discarded polyester products as resources is extremely important in realizing Circular Economy. “Reuse” and “Recycling” can be ways to realize Circular Economy for polyester products, and “Reuse” is an extremely effective way of reducing environmental impact. However, if you continue to “Reuse”, any product will deteriorate and eventually be discarded. That’s why “Recycling” is also an important to close the cycle.

“Recycling” can be classified into three types, “Thermal Recycling”, “Mechanical Recycling”, and “Chemical Recycling”. “Thermal Recycling” is a recycling method that utilizes the “Thermal Energy” generated when incinerating waste. However, it cannot be used as raw materials for new products, so “Thermal Recycling” is not usually recognized as “Recycling”. “Mechanical Recycling” is the recycling of “Products” into “Products”, but same as “Reuse”, there is a problem that the quality of product deteriorates when recycling is repeated. “Chemical Recycling” can solve these problems. “Chemical Recycling” can basically guarantee the same quality as virgin products. Since it can be recycled and regenerated repeatedly, it is possible to minimize waste disposal, and it can be an effective means of contributing to the realization of Circular Economy.

Teijin has a track record of operating large-scale plants using chemical recycling technology. This chemical recycling technology is called dimethyl terephthalate (DMT), which decomposes and converts polyester (PET) and then repolymerizes it. Notably, the DMT method removes dyes and impurities, making it possible to manufacture recycled PET with the same quality as petroleum-derived PET. Therefore, it can be applied not only to textiles, but also to all kinds of polyester products such as PET bottles, food trays, and industrial films.

Furthermore, in order to develop a business that licenses this chemical recycling technology globally, Teijin, JGC Holdings corporation, which has general engineering experience and know-how in plant construction, and ITOCHU Corporation, which has global network in the textile industry jointly established a commercial joint venture, RePEaT Co., Ltd. in January 2023.

RePEaT will license recycling technology that was first developed by Teijin and then jointly streamlined and packaged by JGC and Teijin. Customers in Japan and other countries are expected to use the technology to launch chemical-recycling businesses for the production of polyester products. In addition to technology licensing, RePEaT will provide consulting services to help customers establish ecosystems that collect used polyester fiber products for reuse as raw materials, thereby contributing to a more sustainable world through recycling.

In February 2023, RePEaT signed a license agreement with Zhejiang Jianxin Jiaren New Materials Co., Ltd. on chemical recycling technology for polyester (PET) products, which is a big step forward.

Image: The RePEat process